placename:- Greenside Mine

"Greenside Mine (Lead) / Sluice / Crushing Mill / Wheel / Wheel"

and related plant on the nearby fells

goto source

goto sourcePage 33:- "... Patterdale, though now the poorest place that I am acquainted with, was once the seat of peace and plenty. Almost every man had a small freehold, whose annual produce, (though perhaps not equal to the daily expenditure of the rich and gay,) not only maintained him and his family in a comfortable manner, but even enabled many among them to amass small sums of money. The scene is now changed; vice and poverty sit pictured in almost every countenance, and the rustic fireside is no longer the abode of peace and contentment. The lamentable change took place about thirty years ago: at that time some lead mines wre (sic) wrought in this Dale, and of course a number of miners were brought from different parts for that purpose. These fellows, who are in general the most abandoned, wicked, and profligate part of mankind, no sooner settled here, than they immediately began to propagate their vices among the innocent unsuspecting inhabitants. The farmer listened greedily to stories of places he had never seen, and by that means was brought to drink, and at length to game with these miscreants: his daughters, allured by promises, were seduced; even those who withstood promises, and were actually married, were, upon the stopping of the mines, deserted by their faithless husbands, and left to all the horrors of poverty and shame. Thus we may see as it were in epitome, the baleful effects of vice upon society at large."

GAR2NY31.jpg

"Lead Mine"

circle

item:- JandMN : 82.1

Image © see bottom of page

placename:- Greenside Mine

item:- South Cross Course; North Cross Course; galena; silver; blende; barytes; iron pyrites; High Level; Low Level; Lucy Tongue Level; Smith's Shaft; electric locomotive; tramroad; rock drill; turbine; water wheel; chimney, lead mine; lead ore

goto source

goto sourcepage 122:- "GREENSIDE MINE."

"This mine, although it cannot be if the antiquity of Coniston and Goldscope, or the world-wide celebrity of the Graphite Mine, is one of the most valuable mines in the North of England. It is situated near the head of Ullswater, in a spur of the Helvellyn range. The bearing of the vein is north and south, and its unusually small hade of about eighteen inches per fathom is towards the east. It is intersected by several east and west cross courses, which heave it a few feet to the west. The most important of these are the South Cross Course, which practically forms the southern boundary of the ore-bearing ground, and the North Cross Course which traverses the most prolific portion of the mine. None of the cross courses contain ore, but there is one or more dykes of igneous rock running in an east and west direction, the most important of which strikes the vein at the northern end of the mine, then turns south a right angles, and for a considerable distance runs parallel to and in contact with the vein, and there can be but little doubt that it was the circulation of thermal water which followed the filling of the dyke fissure by a fluid igneous magma, and to its mingling with the thermal water flowing in the two great cross courses that produced the rich and extensive deposits of ore."

"These dykes are the same character and crystalline structure as the Armboth Dyke, on Armboth Fell, one branch of which crosses Thirlmere and penetrates Helvellyn near the seventh milestone on the road to Grasmere, and it is highly probable that all these dykes were formed at the same time and were filled from the same reservoir of molten rock."

"The western or lying cheek of the vein is moderately well defined at times and constant when barren of ore, but there is no regular cheek on the hanging or eastern side. There is some quartz in the vein and dyke material, which consists chiefly of a light grey felsitic rock, through which the immense number of strings of galena are interspersed, varying in thickness from an eighth of an inch to two or three inches, and these spread through the rock to such an extent on the eastern side of the vein, that in the upper part of the mine the ground could be cut away profitably to a width of from thirty to fifty, and in some cases sixty feet. In the lower part of the mine the ore is more concentrated, and the stopes do not average more than from eight to nine feet in width. The ore-bearing ground is about two hundred and sixty fathoms in length, but in the middle portion of the mine it is divided into two parts by a pillar of barren ground about twenty fathoms in length."

"The principal ore is galena, which produces, when smelted, about 80 per cent. of lead, and 12 ounces of silver per ton; there are also small quantities of blende, barytes, and iron pyrites."

goto source

goto sourcepage 123:- "The mine was first opened in the latter part of the eighteenth century, but was not worked extensively until about the year 1825. Before that time it had been wrought chiefly near the summit of the mountain, and the greater part of the ore obtained there was carried over the mountain, through the Vale of St. John, and by Keswick, to the smelt mill at Stoney Croft Gill. A lower level had, however, been commenced about 50 fathoms below the summit, and when the pioneers of the present proprietary took possession of the mine they pushed forward this level, which is now called the "High Level"; and afterwards a flank level, called the "Low Level," was driven to the vein from Lucy Tongue Gill, about 36 fathoms below the high level. A shaft was then sunk about 36 fathoms deep, and finding that the ore continued downwards, another flank level, called "Lucy Tongue Level," was driven to the vein 82 fathoms below the low level. This was a very costly work, as it had to be driven about 800 fathoms before the vein was reached; this was accomplished in 1868, after fourteen years' work."

"In 1864 the shaft in the low level was sunk an additional 13 fathoms, and eighteen years later it was sunk through the remaining distance of 33 fathoms to Lucy Tongue Level. In 1862 a shaft was sunk in Lucy Tongue Level to a depth of 20 fathoms, and an additional 20 fathoms were sunk in 1875, and another 20 fathoms in 1890."

"As this shaft was sunk vertically, and being started west of the vein which dips about 18% from the vertical eastward, a cross-cut at the 60 fathom level was required to intersect the vein 22½ fathoms in length. This, and the shaft not being in central position, the sinking was suspended, and a new shaft, called "Smith's Shaft," was started about 75 fathoms further north and 22½fathoms to the east of the vein at Lucy Tongue Level in the year 1891, having an electrical equipment for winding the stuff from the sinkers. The shaft was sunk 40 fathoms and a connection made with that level, when the small electric hoist was replaced by a larger, cages to lift the full wagons of ore stuff installed, and the sinking continued with the small hoist to the 60-fathom level, and so continued to the depths for the 75 and 90-fathom levels. It is worthy of remark that these electrical winding machines were the first of their kind erected in any metalliferous mine in this country. The deepest level is 105 fathoms deep below the Lucy Tongue Level, and is served by an electric winder and self-tipping skips."

"As it will be seen, the shafts are not directly connected with the surface, being about one mile inside the mine from the entrance of the Lucy Tongue Level, through which the whole of the production of the mine is hauled by an electric locomotive which was installed in 1893, another record for such equipment; formerly seven horses were required to do the work of the locomotive."

goto source

goto sourcepage 125:- "Six compressed-air rock drills are supplied by a Walker's Air Compressor driven by an electric motor, and fixed underground two miles from the generating station near Helvellyn."

"In 1862 an immense mass of vein material that had been undermined in one of the wide stopes became detached and dropped or rather crushed down into the stope, fortunately without injuring any of the miners. It measured about 28 fathoms in length and depth, and from 8 to 10 fathoms in thickness, and contained upwards of 6,000 cubic fathoms of rock and vein-stone. The ore in this mass was valued by one of the agents at L80,000, but it is doubtful whether that was realised on breaking it up, a work that occupied several years."

"Owing to the hard nature of the vein-material, and the way in which the ore is interspersed through it, the dressing requires a great deal of labour. After being picked at the grates the orey material is carried to the crushing mills, for which the rougher portion of it is prepared by passing through Blake's patent crushers, thence to the crusher rolls. The crushed material is conveyed to a number of Green's patent dressing machines, which separate the ore from the refuse and make it ready for the smelt mill."

"Of late years great improvements have been made throughout the washing and dressing plant by way of replacing the old circular Buddles, by Record Vanner Tables, treating the fines from the Classifiers after leaving the Jigging Houses, the finest stuff - "Slimes" - going to Luhrig Buss Tables and Belt Vanners, the whole plant forming a continuous dressing arrangement, without recourse to handling the material a second time."

"Formerly this machinery was propelled by two powerful turbines, also three large and several small water-wheels. One water-wheel was constantly employed in compressing air for the rock-drills that have been in use in the mine about thirty years. In addition to the machinery outside, there were two powerful hydraulic engines in the mine, one at the head of the shaft in the low level, by which the work was hauled up from the workings below, and the other at the head of the shaft in Lucy Tongue Level. All the old levels in the upper part of the mine were used for storing water to supply the hydraulic engines; the turbines and water-wheels were supplied from the same natural reservoirs at Red Tarn and Kepple Cove Tarn. Now all this is changed, and the motive power for pumping, drawing, hauling, crushing, and other purposes is supplied by the electrical plant."

"The ore is smelted on the mine and the silver extracted from it. The smelting and refining furnaces are well adapted for the work they have to perform. The chimney has been carried up the side of the mountain for a distance of 1½miles, in order that every facility may be afforded for the condensation of the lead that flies off in vapour from the furnaces. The chimney is provided"

goto source

goto sourcepage 126:- "with man-holes at intervals, and it is swept periodically, and the soot and condensed lead are carried back to the furnaces."

"About the year 1862, when the great fall of vein-material took place, and for some time afterwards, the mine was in a state of great prosperity; the low level shaft was in full work, and making large returns, and a considerable quantity of ore was also being raised in the high level. In 1872 the produce of the mine was 1,156 tons of pig lead, worth £ 26,588, and the silver extracted from it would be about 9cwt. 2qtrs. 20lbs. avoirdupois, value £ 4,335. About twenty-eight years ago, when the price of lead was low, the upper part of the mine had been greatly exhausted, the appearance of the lower part was discouraging, and it seemed doubtful whether or not the mine could be kept working profitably, moreover the lease was nearly at an end, and it became necessary to consider the situation seriously. After mature consideration, it was decided to renew the lease, more capital was subscribed, a new sump was sunk in Lucy Tongue Level, for ventilation, 190 fathoms north of the old shaft, and the mine was restored to good working order. The annual produce of the mine during the years 1885, 1886, 1887, and 1888 averaged about 800 tons of pig lead, the output in the last of the four being 1,000 tons. The yield in 1910 and 1911 was 3,091 tons of argent pig lead. value £39,499."

"In a pamphlet published in 1876 by J. H. Murchison, F.R.G.S., entitled "British Lead Mines," it is recorded that "about 60,000 tons of lead ore had been raised from Greenside Mine prior to that time, yielding 40,000 tons of smelted lead and 600,000 ozs. of silver, worth respectively about £800,000 and £150,000, and the profits divided had been about £300,000."

placename:- Greenside Mine

PST2NY31.jpg

"GREENSIDE MINE"

mine symbol

item:- JandMN : 162.2

Image © see bottom of page

placename:- Greenside Mine

click to enlarge

click to enlargePST330.jpg

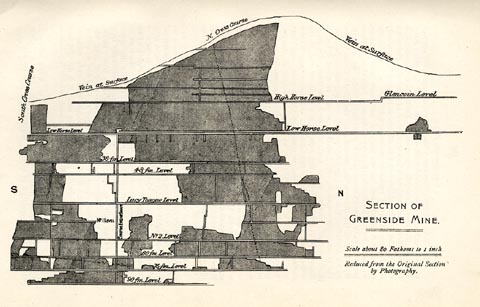

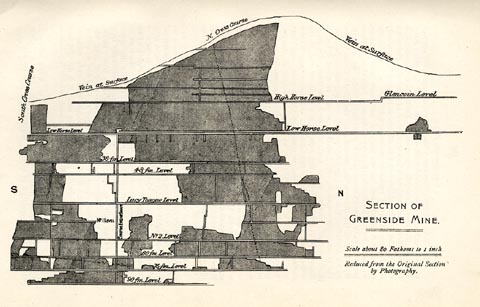

On p.121 of Mines and Mining in the English Lake District, by John Postlethwaite.

printed, lower right "SECTION OF / GREENSIDE MINE. / Scale about 80 Fathoms to 1 inch. / Reduced from the Original Section / by Photography."

item:- JandMN : 162.32

Image © see bottom of page

placename:- Greenside Mine

click to enlarge

click to enlargePST331.jpg

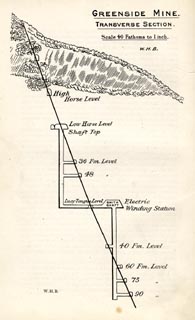

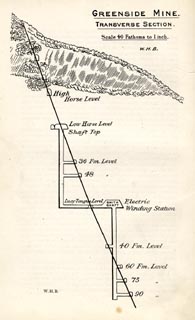

On p.124 of Mines and Mining in the English Lake District, by John Postlethwaite.

printed, upper right "GREENSIDE MINE. / TRANSVERSE SETION. / Scale 40 Fathoms to 1 inch. / W.H.B."

item:- JandMN : 162.33

Image © see bottom of page

placename:- Greenside Mine

item:- South Cross Course; North Cross Course; galena; silver; blende; barytes; iron pyrites; High Level; Low Level; Lucy Tongue Level; Smith's Shaft; electric locomotive; tramroad; rock drill; turbine; water wheel; chimney, lead mine; lead ore

goto source

goto sourcepage 122:- "GREENSIDE MINE."

"This mine, although it cannot be if the antiquity of Coniston and Goldscope, or the world-wide celebrity of the Graphite Mine, is one of the most valuable mines in the North of England. It is situated near the head of Ullswater, in a spur of the Helvellyn range. The bearing of the vein is north and south, and its unusually small hade of about eighteen inches per fathom is towards the east. It is intersected by several east and west cross courses, which heave it a few feet to the west. The most important of these are the South Cross Course, which practically forms the southern boundary of the ore-bearing ground, and the North Cross Course which traverses the most prolific portion of the mine. None of the cross courses contain ore, but there is one or more dykes of igneous rock running in an east and west direction, the most important of which strikes the vein at the northern end of the mine, then turns south a right angles, and for a considerable distance runs parallel to and in contact with the vein, and there can be but little doubt that it was the circulation of thermal water which followed the filling of the dyke fissure by a fluid igneous magma, and to its mingling with the thermal water flowing in the two great cross courses that produced the rich and extensive deposits of ore."

"These dykes are the same character and crystalline structure as the Armboth Dyke, on Armboth Fell, one branch of which crosses Thirlmere and penetrates Helvellyn near the seventh milestone on the road to Grasmere, and it is highly probable that all these dykes were formed at the same time and were filled from the same reservoir of molten rock."

"The western or lying cheek of the vein is moderately well defined at times and constant when barren of ore, but there is no regular cheek on the hanging or eastern side. There is some quartz in the vein and dyke material, which consists chiefly of a light grey felsitic rock, through which the immense number of strings of galena are interspersed, varying in thickness from an eighth of an inch to two or three inches, and these spread through the rock to such an extent on the eastern side of the vein, that in the upper part of the mine the ground could be cut away profitably to a width of from thirty to fifty, and in some cases sixty feet. In the lower part of the mine the ore is more concentrated, and the stopes do not average more than from eight to nine feet in width. The ore-bearing ground is about two hundred and sixty fathoms in length, but in the middle portion of the mine it is divided into two parts by a pillar of barren ground about twenty fathoms in length."

"The principal ore is galena, which produces, when smelted, about 80 per cent. of lead, and 12 ounces of silver per ton; there are also small quantities of blende, barytes, and iron pyrites."

goto source

goto sourcepage 123:- "The mine was first opened in the latter part of the eighteenth century, but was not worked extensively until about the year 1825. Before that time it had been wrought chiefly near the summit of the mountain, and the greater part of the ore obtained there was carried over the mountain, through the Vale of St. John, and by Keswick, to the smelt mill at Stoney Croft Gill. A lower level had, however, been commenced about 50 fathoms below the summit, and when the pioneers of the present proprietary took possession of the mine they pushed forward this level, which is now called the "High Level"; and afterwards a flank level, called the "Low Level," was driven to the vein from Lucy Tongue Gill, about 36 fathoms below the high level. A shaft was then sunk about 36 fathoms deep, and finding that the ore continued downwards, another flank level, called "Lucy Tongue Level," was driven to the vein 82 fathoms below the low level. This was a very costly work, as it had to be driven about 800 fathoms before the vein was reached; this was accomplished in 1868, after fourteen years' work."

"In 1864 the shaft in the low level was sunk an additional 13 fathoms, and eighteen years later it was sunk through the remaining distance of 33 fathoms to Lucy Tongue Level. In 1862 a shaft was sunk in Lucy Tongue Level to a depth of 20 fathoms, and an additional 20 fathoms were sunk in 1875, and another 20 fathoms in 1890."

"As this shaft was sunk vertically, and being started west of the vein which dips about 18% from the vertical eastward, a cross-cut at the 60 fathom level was required to intersect the vein 22½ fathoms in length. This, and the shaft not being in central position, the sinking was suspended, and a new shaft, called "Smith's Shaft," was started about 75 fathoms further north and 22½fathoms to the east of the vein at Lucy Tongue Level in the year 1891, having an electrical equipment for winding the stuff from the sinkers. The shaft was sunk 40 fathoms and a connection made with that level, when the small electric hoist was replaced by a larger, cages to lift the full wagons of ore stuff installed, and the sinking continued with the small hoist to the 60-fathom level, and so continued to the depths for the 75 and 90-fathom levels. It is worthy of remark that these electrical winding machines were the first of their kind erected in any metalliferous mine in this country. The deepest level is 105 fathoms deep below the Lucy Tongue Level, and is served by an electric winder and self-tipping skips."

"As it will be seen, the shafts are not directly connected with the surface, being about one mile inside the mine from the entrance of the Lucy Tongue Level, through which the whole of the production of the mine is hauled by an electric locomotive which was installed in 1893, another record for such equipment; formerly seven horses were required to do the work of the locomotive."

goto source

goto sourcepage 125:- "Six compressed-air rock drills are supplied by a Walker's Air Compressor driven by an electric motor, and fixed underground two miles from the generating station near Helvellyn."

"In 1862 an immense mass of vein material that had been undermined in one of the wide stopes became detached and dropped or rather crushed down into the stope, fortunately without injuring any of the miners. It measured about 28 fathoms in length and depth, and from 8 to 10 fathoms in thickness, and contained upwards of 6,000 cubic fathoms of rock and vein-stone. The ore in this mass was valued by one of the agents at L80,000, but it is doubtful whether that was realised on breaking it up, a work that occupied several years."

"Owing to the hard nature of the vein-material, and the way in which the ore is interspersed through it, the dressing requires a great deal of labour. After being picked at the grates the orey material is carried to the crushing mills, for which the rougher portion of it is prepared by passing through Blake's patent crushers, thence to the crusher rolls. The crushed material is conveyed to a number of Green's patent dressing machines, which separate the ore from the refuse and make it ready for the smelt mill."

"Of late years great improvements have been made throughout the washing and dressing plant by way of replacing the old circular Buddles, by Record Vanner Tables, treating the fines from the Classifiers after leaving the Jigging Houses, the finest stuff - "Slimes" - going to Luhrig Buss Tables and Belt Vanners, the whole plant forming a continuous dressing arrangement, without recourse to handling the material a second time."

"Formerly this machinery was propelled by two powerful turbines, also three large and several small water-wheels. One water-wheel was constantly employed in compressing air for the rock-drills that have been in use in the mine about thirty years. In addition to the machinery outside, there were two powerful hydraulic engines in the mine, one at the head of the shaft in the low level, by which the work was hauled up from the workings below, and the other at the head of the shaft in Lucy Tongue Level. All the old levels in the upper part of the mine were used for storing water to supply the hydraulic engines; the turbines and water-wheels were supplied from the same natural reservoirs at Red Tarn and Kepple Cove Tarn. Now all this is changed, and the motive power for pumping, drawing, hauling, crushing, and other purposes is supplied by the electrical plant."

"The ore is smelted on the mine and the silver extracted from it. The smelting and refining furnaces are well adapted for the work they have to perform. The chimney has been carried up the side of the mountain for a distance of 1½miles, in order that every facility may be afforded for the condensation of the lead that flies off in vapour from the furnaces. The chimney is provided"

goto source

goto sourcepage 126:- "with man-holes at intervals, and it is swept periodically, and the soot and condensed lead are carried back to the furnaces."

"About the year 1862, when the great fall of vein-material took place, and for some time afterwards, the mine was in a state of great prosperity; the low level shaft was in full work, and making large returns, and a considerable quantity of ore was also being raised in the high level. In 1872 the produce of the mine was 1,156 tons of pig lead, worth £ 26,588, and the silver extracted from it would be about 9cwt. 2qtrs. 20lbs. avoirdupois, value £ 4,335. About twenty-eight years ago, when the price of lead was low, the upper part of the mine had been greatly exhausted, the appearance of the lower part was discouraging, and it seemed doubtful whether or not the mine could be kept working profitably, moreover the lease was nearly at an end, and it became necessary to consider the situation seriously. After mature consideration, it was decided to renew the lease, more capital was subscribed, a new sump was sunk in Lucy Tongue Level, for ventilation, 190 fathoms north of the old shaft, and the mine was restored to good working order. The annual produce of the mine during the years 1885, 1886, 1887, and 1888 averaged about 800 tons of pig lead, the output in the last of the four being 1,000 tons. The yield in 1910 and 1911 was 3,091 tons of argent pig lead. value £39,499."

"In a pamphlet published in 1876 by J. H. Murchison, F.R.G.S., entitled "British Lead Mines," it is recorded that "about 60,000 tons of lead ore had been raised from Greenside Mine prior to that time, yielding 40,000 tons of smelted lead and 600,000 ozs. of silver, worth respectively about £800,000 and £150,000, and the profits divided had been about £300,000."

placename:- Greenside Mine

PST2NY31.jpg

"GREENSIDE MINE"

mine symbol

item:- JandMN : 162.2

Image © see bottom of page

placename:- Greenside Mine

click to enlarge

click to enlargePST330.jpg

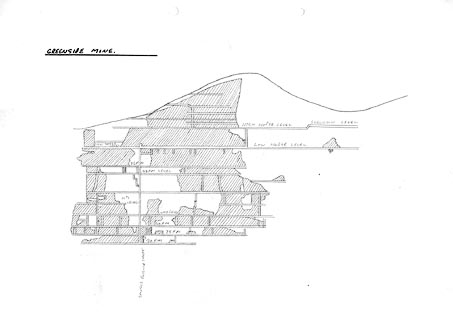

On p.121 of Mines and Mining in the English Lake District, by John Postlethwaite.

printed, lower right "SECTION OF / GREENSIDE MINE. / Scale about 80 Fathoms to 1 inch. / Reduced from the Original Section / by Photography."

item:- JandMN : 162.32

Image © see bottom of page

placename:- Greenside Mine

click to enlarge

click to enlargePST331.jpg

On p.124 of Mines and Mining in the English Lake District, by John Postlethwaite.

printed, upper right "GREENSIDE MINE. / TRANSVERSE SETION. / Scale 40 Fathoms to 1 inch. / W.H.B."

item:- JandMN : 162.33

Image © see bottom of page

placename:- Greenside Mine

click to enlarge

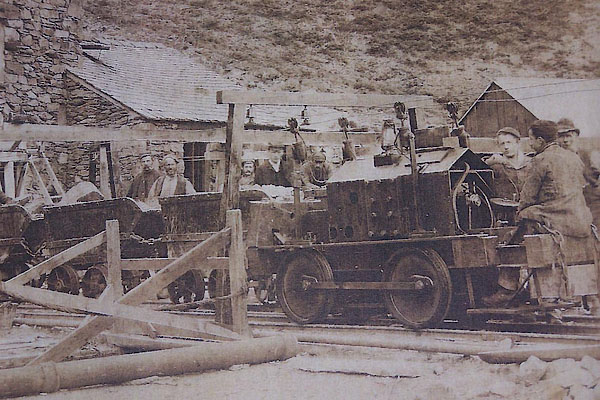

click to enlargeKMR26.jpg

"GREENSIDE MINE"

item:- private collection : 82

Image © see bottom of page

CET36.jpg (taken 14.3.2016)

CET37.jpg (taken 14.3.2016)

BOV32.jpg (taken 17.3.2008)

BVO02.jpg (taken 19.10.2011)

BVO03.jpg (taken 19.10.2011)

CCC91.jpg Culvert over leat,

(taken 18.11.2014)

CCC92.jpg Bridge on leat,

(taken 18.11.2014)

CCC93.jpg Bridge on leat,

(taken 18.11.2014)

CCC95.jpg Leat,

(taken 18.11.2014)

CCC96.jpg Leat,

(taken 18.11.2014)

CCD02.jpg (taken 18.11.2014)

CCD03.jpg (taken 18.11.2014)

CCD08.jpg Building remains,

Possibly a hydroelectric plant at the end of the pipeline?

(taken 18.11.2014)

CCD10.jpg Tip wagon.

(taken 18.11.2014)

CCD11.jpg Industrial litter

(taken 18.11.2014)

BOH52.jpg Structure.

(taken 17.10.2007)

BOH53.jpg Structure.

(taken 17.10.2007)

BMH35.jpg New electric locomotive, about 1893.

Courtesy of Threlkeld Mining Museum.

Adams, John: 1988: Mines of the Lake District Fells: Dalesman Books (Lancaster, Lancashire):: ISBN 0 85206 931 6